WINSMART

Smart, lightweight, cost-effective and energy efficient windows based on novel material combinations.

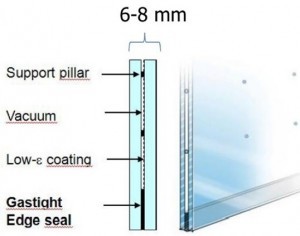

The main goal of the project is to develop a smart window system that will contribute to meeting the energy efficiency targets of the building industry by 2020. This goal will be achieved through a new vacuum insulation glazing (VIG) solution combined with newly developed and robust switchable glazing systems mounted in durable and energy efficient sash and frame. For maximum impact and overall effectiveness, the new model window will be scalable for use in a range of building scenarios (including renovation/retro-fitting of existing structures), be inexpensive and easy to install, be lightweight, durable and of reduced carbon footprint compared to current available solutions. VIG offers the potential of 2-5 times higher insulation performance with a doubly glazed pane, at the same time providing an extremely slim and lightweight solution. In addition to high thermal performance, the smart windows will have improved control functions including switchable optical properties and exterior surface protection (anti-fogging, easy to clean, scratch resistant etc.).

Featured inAMANAC 3rd Newsletter!

Vacuum Insulation Glazing-VIG

SMARTBLIND

Development of an active film for smart windows with inkjet method. Application to a building envelope component: autonomous smart device.

The SMARTBLIND project aims at developing an Energy Efficient Smart Window including a hybrid film constituted of an electrochromic LC film and a photovoltaic film both printed on the same long-lasting flexible substrate. The realization process will be implemented thanks to electrochromic and photovoltaic inks especially formulated to be ink-jet printed. A reduction of the windows U-value is targeted by combining the hybrid film to an appropriate window frame. An important part of the SmartBlind project will furthermore be devoted to the related parts, such as connectors and film control, sustainability, life cycle and recyclability. More particularly, the SmartBlind consortium has defined 4 main objectives:

- To reduce weight by 50% compared to glass window, while offering transparency and flexibility.

- To improve the optical response time of windows while enabling the switching of large panes.

- To integrate an electronic control system with an embedded power source.

- To guarantee a low-cost industrial solution adaptable to large and shaped surfaces.

MEM4WIN

Ultra thin glass membranes for advanced, adjustable and affordable quadruple glazing windows for zero-energy buildings.

The goal of MEM4WIN is to introduce a novel Integrated Glazing Unit (IG-Unit) for quadruple glazing containing ultra-thin glass membranes dedicated as frameless openable windows for direct application in facades. A new tempered ultra-thin glass membranes (reached thickness so far: 1.3 mm) are employed. Due to this approach U-values of 0.3 W/m²K can be achieved reducing weight by more than 50% and costs by 20%. In addition, MEM4WIN will implement ink-jet printed organic photovoltaics (OPVs) and fully integrated solar thermal collectors for energy harvesting and micro mirrors for energy control and advances day lighting. Fabrication costs will further be reduced by replacing conventional and cost intensive materials used for contacts like ITO and silver by graphene. MEM4WIN will also introduce production methods like roll-to-plate and ink-jet printing to fabricate contacts for OPVs.

Integrated Glazing Unit (IG-Unit) for quadruple glazing containing ultra-thin glass membranes

Featured in AMANAC 2nd Newsletter!

HARWIN

Harvesting solar energy with multifunctional glass-polymer windows

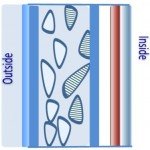

One major direction of material development in HarWin is based on glass particle reinforcement of laminated glazing and glass fibre reinforcement of light weight polymer-glass-composite frames with the aim to significantly reduce the oveall weight of windows while further improving their U-value. Another goal is to reduce embodied energy consumption and material usage, therefore life cycle environmental analysis is used as guiding tool for the development of the new glazing and frame window materials. New additional functionality of the glazing is achieved by integrated functional coatings and employment of intelligent phase changing materials as well as introduction of novel glass-based materials with wavelength management capability.

These new windows will combine heat and noise control by means of new laminated and glass particle reinforced composites for glasing which are integrated into light weight polymer foam-glass fibre reinforced composite framing. On long term, the windows developed within HarWin will enable creation of a new type of buildings, where merging of functionalities currently assigned separately to windows and architectural glass will result in a new definition of multifunctional façade, adjustable according to geographic and cultural needs.

- Glass Particle Reinforced

- Coated Glass-Flakes, stack

- Flake, side view, dyed

Featured in AMANAC 2nd Newsletter!

EELICON

Enhanced Energy Efficiency and Comfort by Smart Light Transmittance Control

EELICON is concerned with an innovative switchable light transmittance technology developed previously in projects co-funded by the EU Framework Programmes. The core of this development are mechanically flexible and light-weight electro-chromic (EC) film devices based on a conductive polymer nano-composite technology with a unique property profile far beyond the current state-of-the art, opening the possibility to retrofit existing windows with electrically dimmable plastic film.

According to life cycle assessment studies, considerable energy savings may result when such films are included in appliance doors, aircraft cabin windows, and automotive sunroofs. The development has been driven to the pilot-line production stage however, the decisive step from research to innovation could not yet be accomplished for a number of technical and economic reasons. To overcome this gap, EELICON will tackle existing drawbacks by removing equipment limitations, automating processes, and establishing a high-throughput prototype production for a cost-effective high performance EC film technology in Europe.

LaWin

Large Area Fluidic Window

The Horizon 2020-funded project ‘Large-Area Fluidic Windows’ (LaWin) is intended to develop functional façades and window modules, together with an integrated production process to achieve an unmatched readiness to market. The core of the technology is based on structured glass which contains microfluidic channels through which a functional fluid circulates. As an example, this liquid will make it possible to automatically adjust the incidence of light or to harvest exterior heat which will then be transported to a heat pump.

The homepage is under construction. More information is provided by project manager/coordination office.